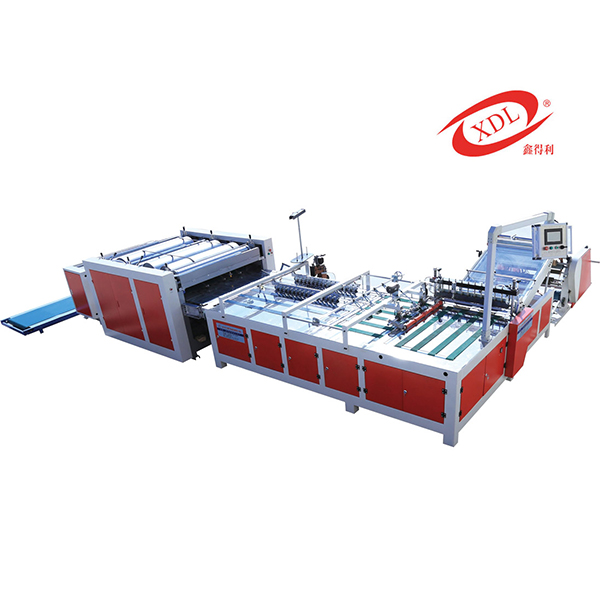

Smokeless knife cutting, sewing, printing and collecting machine

1. Smokeless cold cutting technology: Environmentally friendly and highly efficient. Utilizing a combination of high-strength, wear-resistant alloy steel cold blades and precision blade holders, the cutting process is free of high temperatures, smoke, and odors, fully complying with environmental production standards and improving the workshop working environment. The cut is smooth and even, without burrs or scorched edges, offering high cutting precision and significantly improved cut strength compared to traditional hot cutting. This effectively reduces subsequent issues such as material leakage during sewing and packaging damage. Simultaneously, the cold blade has a long service life, significantly reducing blade replacement costs.

2. Integrated production process, significantly boosting capacity: The four major processes of cutting, sewing, printing, and material collection are highly integrated, eliminating the need for manual handling of semi-finished products and significantly shortening the production process. Equipped with an intelligent continuous feeding system and automatic receiving device, it can achieve 24-hour uninterrupted production. The single unit has high finished product processing efficiency, which greatly improves the overall efficiency compared to decentralized production lines and significantly reduces labor input costs.

3. Precise and Interlocking Control, Stable and Controllable Quality: Equipped with an industrial-grade PLC central control system, it links CCD vision positioning, servo feeding, and intelligent tension adjustment modules to achieve real-time synchronization of parameters for each process. Printing ensures precise registration, clear and fade-resistant patterns; sewing stitches are uniform and tight, with automatic alarms for broken or loose threads; the material receiving system employs a layered and neat stacking design, resulting in an extremely high finished product qualification rate and ensuring consistency in mass production.

4. Flexible and widely adaptable, with strong customization capabilities: It supports multi-specification cutting size adjustment and can realize a variety of cutting styles such as flat mouth and oblique mouth. The printing system is compatible with multi-color customization and is suitable for different materials such as ordinary woven bags, laminated woven bags, and ton bag substrates. The equipment is equipped with a large-size color touch screen. Parameter presetting and specification switching can be completed with one click. It has a built-in memory function for commonly used specifications, making production changes and debugging convenient and fast.

5. Energy-saving, durable, and worry-free, with optimized operation and maintenance costs: Adopting energy-saving servo motors and intelligent frequency conversion technology, the overall energy consumption of the machine is significantly reduced compared to traditional multi-equipment combinations; the printing system is equipped with an ink recycling device, resulting in high ink utilization; the machine body is welded with high-strength steel, and key components are selected from high-quality brands, resulting in a low failure rate. Routine maintenance only requires periodic cleaning of the ink path and lubrication of transmission components, significantly reducing maintenance costs compared to traditional production lines.

Smokeless knife cutting, sewing, printing and collecting integrated machine product introduction

I. Product Overview

The smokeless knife cutting, printing and collecting all-in-one machine is a full-process automated woven bag production equipment that integrates "smokeless precise cutting, high-speed and firm sewing, clear pattern printing, and automatic and neat collection of materials". It is specially designed for PP and PE plastic woven bags, composite woven bags and various flexible packaging materials. This equipment innovatively uses smokeless cold cutting technology to replace traditional thermal cutting, eliminating smoke and odor during the cutting process from the source. With an intelligent linkage control system, it seamlessly connects the four core processes of cutting, sewing, printing, and collecting materials in woven bag production, completely eliminating the cumbersome transfer links of traditional decentralized production. It is suitable for the mass production of woven bags in multiple industries such as feed, chemicals, fertilizers, grain, building materials, logistics, etc. It can flexibly adapt to customized production tasks of different specifications and different printing requirements. It is the core equipment to realize environmental protection, efficiency and integrated upgrade of woven bag production.

II. Core Product Advantages

1. Smokeless cold cutting technology: Environmentally friendly and highly efficient. Utilizing a combination of high-strength, wear-resistant alloy steel cold blades and precision blade holders, the cutting process is free of high temperatures, smoke, and odors, fully complying with environmental production standards and improving the workshop working environment. The cut is smooth and even, without burrs or scorched edges, offering high cutting precision and significantly improved cut strength compared to traditional hot cutting. This effectively reduces subsequent issues such as material leakage during sewing and packaging damage. Simultaneously, the cold blade has a long service life, significantly reducing blade replacement costs.

2. Integrated production process, significantly boosting capacity: The four major processes of cutting, sewing, printing, and material collection are highly integrated, eliminating the need for manual handling of semi-finished products and significantly shortening the production process. Equipped with an intelligent continuous feeding system and automatic receiving device, it can achieve 24-hour uninterrupted production. The single unit has high finished product processing efficiency, which greatly improves the overall efficiency compared to decentralized production lines and significantly reduces labor input costs.

3. Precise and Interlocking Control, Stable and Controllable Quality: Equipped with an industrial-grade PLC central control system, it links CCD vision positioning, servo feeding, and intelligent tension adjustment modules to achieve real-time synchronization of parameters for each process. Printing ensures precise registration, clear and fade-resistant patterns; sewing stitches are uniform and tight, with automatic alarms for broken or loose threads; the material receiving system employs a layered and neat stacking design, resulting in an extremely high finished product qualification rate and ensuring consistency in mass production.

4. Flexible and widely adaptable with strong customization capabilities: Supports multiple cutting size adjustments, enabling various cutting styles such as flat and beveled edges. The printing system is compatible with multi-color customization and adapts to different materials such as ordinary woven bags, laminated woven bags, and ton bag substrates. The equipment is equipped with a large-size color touchscreen, allowing for one-click parameter presets and specification switching. It also features a built-in memory function for frequently used specifications, making production changeovers and debugging convenient and quick.

5. Energy-saving, durable, and worry-free, with optimized operation and maintenance costs: Adopting energy-saving servo motors and intelligent frequency conversion technology, the overall energy consumption of the machine is significantly reduced compared to traditional multi-equipment combinations; the printing system is equipped with an ink recycling device, resulting in high ink utilization; the machine body is welded with high-strength steel, and key components are selected from high-quality brands, resulting in a low failure rate. Routine maintenance only requires periodic cleaning of the ink path and lubrication of transmission components, significantly reducing maintenance costs compared to traditional production lines.

3. Product parameters

name |

WYRQYS-800 Woven BagSmokeless knife cutting, sewing, printing and collecting machine |

||

Device functions |

1 |

Automatic feeding |

|

2 |

Manual correction (automatic optional) |

||

3 |

Color mark tracking, servo-controlled precise control of bag length and conveying |

||

4 |

Smokeless knife device, automatic pinching, easy-open bag opening |

||

5 |

Forward and reverse tracking can be freely converted. |

||

6 |

PLC centralized control, touch screen to set data, display, record, store and call |

||

7 |

Variable frequency speed control, automatic adjustment of cutting, sewing, and printing speeds |

||

8 |

Automatic inking system (optional) |

||

9 |

Automatic counting, bag stacking, and constant displacement |

||

10 |

Sewing machine automatic thread breakage alarm and stop |

||

11 |

Bag pressing, thread trimming, turning, displacement, electric control, stable and low failure rate |

||

Main technology |

1 |

Unrolled fabric diameter |

≤Ø1400mm |

2 |

Maximum bag width |

≤850mm |

|

3 |

Cut bag length |

≤400-1300mm |

|

4 |

Cutting speed |

30-50pcs/min |

|

5 |

printing color |

1-5 colors |

|

6 |

power |

4KW |

|

7 |

Sewing stitch length |

5-14mm |

|

IV. Product Application and Service Guarantee

This equipment is ideally suited for medium to large-sized woven bag manufacturers, packaging plants, and various industries requiring integrated woven bag production. It is particularly suitable for food packaging, hazardous chemical packaging, and branded packaging production scenarios with stringent environmental requirements. We provide full-cycle service support. Before sales, we can customize exclusive equipment solutions based on the customer's production scale, product specifications, and environmental needs, and offer free trial runs. After sales, we provide on-site installation and commissioning, specialized operator training, and technical consultation services. We have also established a nationwide spare parts warehousing network to ensure rapid response and resolution of equipment malfunctions.