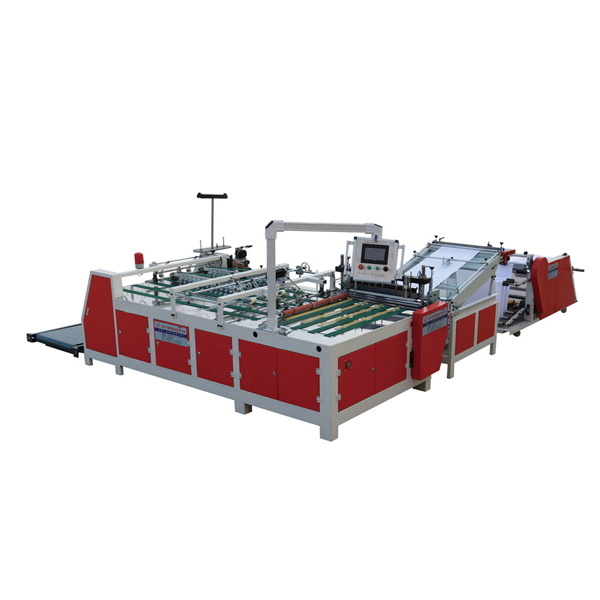

Electric smokeless knife cutting machine

The electric smokeless knife cutting and sewing machine is an integrated processing equipment developed specifically for woven bag production scenarios. It integrates functions such as feeding, folding, cutting, and sewing, and uses electric drive as the core power source to replace the traditional decentralized processing mode.

name |

WYRQ-800 Smokeless Knife Hot Cutting and Sewing Machine for Woven Bags |

||

Device functions |

1 |

Automatic feeding |

|

2 |

Manual correction (automatic optional) |

||

3 |

Color mark tracking, servo-controlled precise control of bag length and conveying |

||

4 |

Smokeless knife device, automatic pinching, easy-open bag opening |

||

5 |

Forward and reverse tracking can be freely converted. |

||

6 |

PLC centralized control, touch screen for setting, displaying, recording, storing, and recalling data. |

||

7 |

Variable frequency speed control, automatic adjustment of cutting and sewing speed |

||

8 |

Automatic counting, bag stacking, and constant displacement |

||

9 |

Sewing machine automatic thread breakage alarm and stop |

||

10 |

Bag pressing, thread cutting, flipping, displacement, electric control, stable operation, and low failure rate. |

||

Main technology |

1 |

Unrolled fabric diameter |

≤Ø1400mm |

2 |

Maximum bag width |

≤850mm |

|

3 |

Cut bag length |

≤400-1300mm |

|

4 |

Cutting speed |

30-50pcs/min |

|

5 |

printing color |

1-5 colors |

|

6 |

power |

4KW |

|

7 |

Sewing stitch length |

5-14mm |

|

Regarding the operation of the woven bag bottom sewing machine, please refer to the operating instructions to avoid various problems caused by unauthorized operation, such as skipped stitches and overheating. Here, Xindeli will explain the repair methods for skipped stitches on the woven bag bottom sewing machine:

1. The thread is not threaded correctly; re-thread according to the "Threading Diagram".

2. The straight needle is not installed correctly; check the height and facing position of the needle so that it is slightly in front of the needle plate hole when the needle moves downward.

3. Straight needle tip broken, bent, etc.; replace the needle.

4. The tip of the curved needle becomes dull; use sandpaper to sharpen the needle, or replace the curved needle.

5. The suture tension is too large or too small; adjust the suture tension to the appropriate level.

6. The curved needle cannot cover the thread loop of the straight machine needle on the left, and the stitches on the right side of the lower decorative thread will skip stitches; the thread loop is too small, so increase the amount of thread pick-up appropriately.

7. The looper should not simultaneously cover the loops of the middle and left straight needles, causing skipped stitches on the middle and left stitches of the lower decorative thread; if the loop is too large, reduce the amount of thread taken up appropriately.