How to choose a woven bag cutting and sewing machine?

The end of the year and the beginning of the new year are the procurement periods for industries such as clothing, bags, and decorations, and also the peak season for woven bag sales. With social development and market demand, woven bag cutting and sewing machines are now widely used. So how can you choose a suitable woven bag cutting and sewing machine? Let's analyze it together.

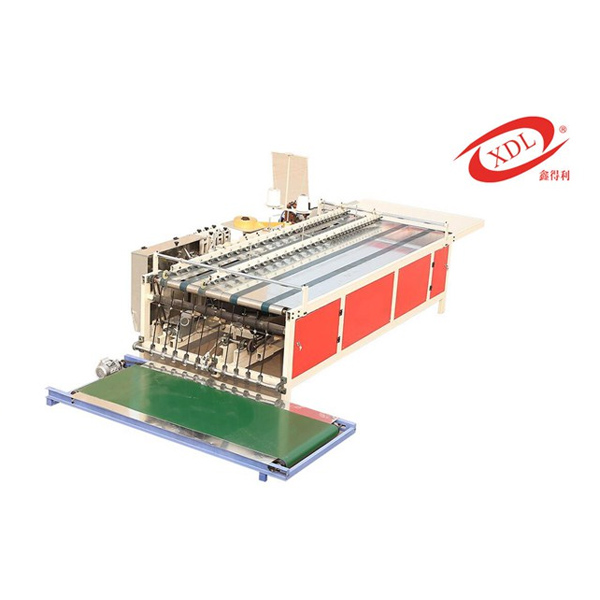

The manufacturer of the woven bag cutting, printing and collecting machine tells you: Generally, the material is first considered when choosing equipment. The cutting seam of the woven bag cutting and sewing machine should be thin, generally 0.10mm-0.20mm, and the cutting surface should be smooth and burr-free. The laser cutting seams of laser processing are thin, fast, and the energy is concentrated. Therefore, the heat transmitted to the material being cut is small, and the deformation of the material is also very small. The cost of mold manufacturing for large products is very high. Laser processing does not require any mold manufacturing. Moreover, laser processing completely avoids the sagging caused by material punching and shearing, which can greatly reduce the production cost of the enterprise and improve the quality of the product. The woven bag cutting and sewing machine has the function of developing new products and shortening the research and development cycle. As soon as the product drawings are formed, laser processing can be performed immediately, and the physical objects of the new products can be obtained in a short time. The laser processing of the woven bag cutting and sewing machine adopts computer programming, which can cut products of different shapes into materials, maximizing the utilization rate of materials.