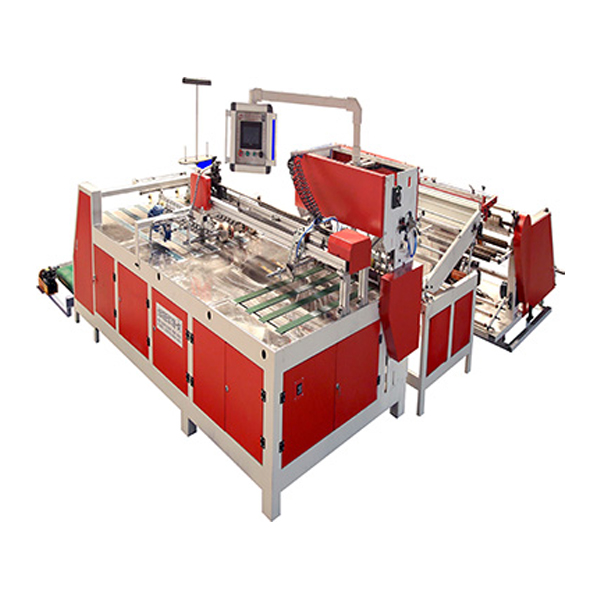

Smokeless cutting machine

The smokeless cutting and sewing machine is a core piece of equipment in the post-processing of woven bags. Specifically designed for PP, PE, and coated woven bags, it innovatively integrates smokeless hot cutting and automated sewing technologies to achieve a fully integrated operation from fabric feeding, automatic correction, precise cutting to seam finishing. The machine employs a linked design between a smokeless cutter head and an intelligent sewing system. During cutting, it uses instantaneous high temperature to complete the cut and simultaneously heat-seal the edges. A built-in negative pressure purification module completely adsorbs trace gases generated during processing, ensuring a smoke-free and odorless process.

I. Product Overview

The smokeless cutting and sewing machine is a core piece of equipment in the post-processing of woven bags. Specifically designed for PP, PE, and coated woven bags, it innovatively integrates smokeless hot cutting and automated sewing technologies, achieving a fully integrated operation from fabric feeding, automatic correction, precise cutting to seam finishing. The machine employs a linked design between the smokeless cutter head and the intelligent sewing system. During cutting, it uses instantaneous high temperature to complete the cut and simultaneously heat-seal the edges. A built-in negative pressure purification module completely adsorbs trace gases generated during processing, resulting in a smoke-free and odorless process. Equipped with an industrial-grade servo drive and PLC centralized control system, it can flexibly adapt to the production of different specifications of woven bags, such as flat bags and valve bags, effectively solving the industry pain points of "dispersed processes and low efficiency" in traditional production.

2. Core advantages

1. Integrated and efficient: The cutting and sewing processes are seamlessly connected, saving time spent on semi-finished product transfer. The efficiency is significantly improved compared to traditional separate equipment. With the continuous feeding mechanism, stable mass production can be achieved 24 hours a day, helping to double the production line capacity.

2. Smokeless and environmentally friendly: The cutting head and purification system operate simultaneously, instantly filtering volatile substances. The workshop environment meets national environmental protection standards, protecting the health of operators and helping enterprises avoid environmental compliance risks, thus creating a green production environment.

3. Intelligent and labor-saving: The high-definition touch screen is intuitive to operate and supports specification memory function. The system automatically adjusts parameters when changing products. Newcomers can be trained in a short time and one person can operate multiple devices, reducing labor input by 80% compared with the traditional mode.

4. Stable quality: Special alloy blades ensure smooth, unfractionated cut edges; the sewing system automatically controls thread tension, resulting in even and strong stitches; the finished bag's sealing and weather resistance are greatly improved, reducing packaging material leakage and waste.

3. Application fields

The equipment is widely adaptable to various scenarios due to its high efficiency: in the agricultural field, it can efficiently process fertilizer, seed, and feed bags, with strong sealing to prevent leakage during transportation; in the industrial field, it can precisely match the processing of heavy packaging bags for cement, building materials, etc., with wear-resistant stitching and resistance to handling; in the grain storage field, it can be used for the production of rice and flour bags, with no loose fibers to avoid food contamination; at the same time, it is also suitable for the batch processing of color-printed laminated bags and express logistics bags, balancing quality and efficiency.