Common sense of operation of woven bag cutting and sewing machine

The manufacturer of the woven bag heat cutting and printing integrated machine tells you: 1. Before starting work, operators must undergo safety education and training and pass the examination before they can start working.

2. Workers must wear work clothes and work hats that meet safety requirements. Wearing earrings, rings, high heels, and slippers is prohibited. Female workers with long hair must tuck their hair inside their safety helmets and must strictly follow the operating procedures.

3. Operate correctly and be careful of electric shock. Before turning on the machine, carefully check to prevent hand injuries from needle pricks or cuts from blades and scissors. Do not sew without material, as this may damage the machine teeth and tooth feet.

4. Do not touch any live parts or related components while the equipment is running or switched on. 5. When performing cutting operations, do not touch the cutter with your hands; keep your hands away from the cutter during operation.

The knife is about 20cm. When stopping the machine, the clutch handle of the feed roller should be loosened. In addition, the equipment must be well grounded.

6. Do not put your hands into the feed rollers, conveyor chains, or power transmission belts while the equipment is running to avoid accidents.

7. Except for professional maintenance, no one is allowed to open or adjust the power control box, operators are prohibited from disassembling machine parts at will, and equipment must not be operated with defects.

8. When handling equipment malfunctions, the emergency stop switch must be pressed to prevent work-related accidents.

9. When the machine is stopped, avoid touching or pressing the operation buttons on the control cabinet with your body or hands to prevent accidents.

10. Operate correctly, maintain the equipment carefully, keep the working environment clean, and ensure safety. For the automatic hot-cutting machine for woven bags, hang the fabric roll on the shaft and press it onto the pressure roller for hot cutting.

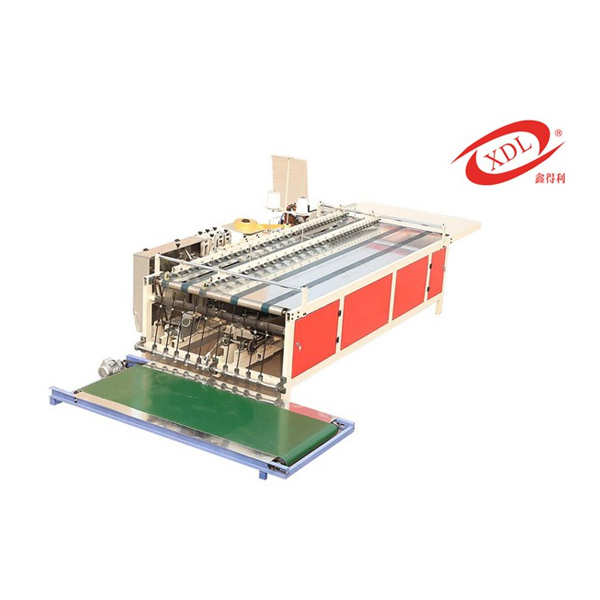

Pneumatic automatic feeding. Automatic deviation correction, color mark tracking, servo-controlled bag length, hot cutting, automatic pinch-off, cold knife device, PLC centralized control, color human-machine interface for setting, displaying, and recording data, variable frequency speed control, automatic counting, automatic bag stacking and conveying.