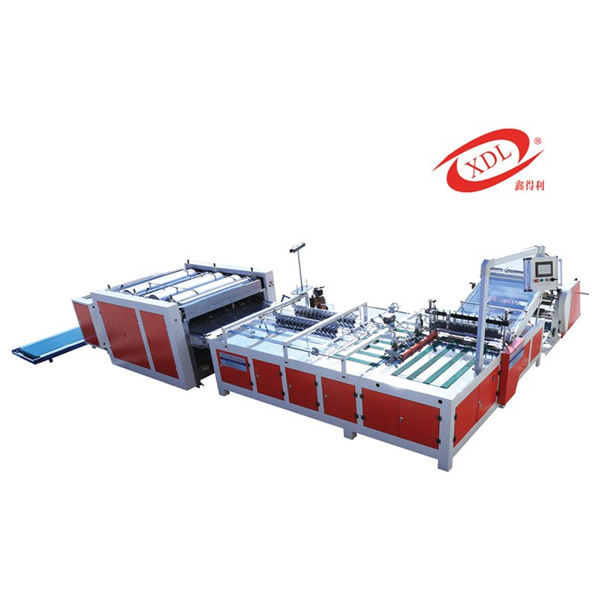

Operating instructions for woven bag printing machine

The manufacturer of the smokeless knife cutting, sewing, printing and receiving machine tells you: 1. The machine operator is responsible for supervising the safety of the machine equipment and the crew.

2. Before starting work, workers must wear their work clothes and shoes neatly, fasten their collars and cuffs, and not put any items that could fall out of their pockets. They must not wear watches or any other jewelry.

3. The printing press has transmission parts that come into contact with the human body, and must be covered with a complete protective cover. It is forbidden to remove the protective cover and start the machine.

4. Before starting the machine, add the required amount of lubricating oil (grease) to all oiling points, lubrication points, and the oil tank. Check the paper feed table for debris, ensure the glue rollers are level, and check the machine for any other items inside.

5. Without approval, personnel not part of the machine crew shall not start or operate the machine. Assistants and apprentices shall work under the guidance of the machine operator.

6. Before starting the machine, check all parts of the machine for any foreign objects. You must give a signal (press the safety bell) and make sure that the area around the machine is safe before starting it.

7. Before running the machine, rotate it several times in reverse and then several times in forward to prevent debris between the rollers from damaging the blanket, printing plate, etc.

8. While the machine is running, it is strictly forbidden to touch the moving working surface with your hands, to repair or wipe the machine, to cross rotating parts, and to keep the machine's protective devices intact.

9. The crew members should strictly adhere to their assigned posts, pay close attention to the operation of all parts of the machine at all times, and immediately stop the machine to handle any problems found.

10. When entering the machine room to inspect the machines, apply oil, and clean up debris, the power must be turned off and the paperboard feeder and receiver must be lowered.

11. When placing the middle foot pedal and adding water, pay attention to personal safety.

12. It is not allowed to wash the rubber roller and the ink fountain at the same time. When washing the rubber cloth and wiping plate, it must be done in a jog motion.

13. No safety devices on the machine may be removed without authorization.

14. Adjust the printing pressure appropriately to ensure the operation of mechanical parts.

15. When cleaning ink stains from the printing cylinder, do not use ink knives, steel knives, or other objects to scrape the printing area. Use appropriate solvents and cloth scraps to clean and wipe the area. Cleaning should be done daily.

16. The work area should be kept clean and unobstructed, with no clutter on the ground, workbench, or around the machines. Maintenance tools and spare parts should be placed in designated locations.

17. During work hours, no one is allowed to laugh, play, or make loud noises around the machine.

18. When the work is finished, clean the machine, protect the printing plate, wipe the blanket, impression cylinder and roller clean, turn off the power, and fill in the work log.

19. Perform regular maintenance and repairs on the machine, and fill out maintenance and repair records.