Woven bag equipment manufacturers tell you: The necessity of mechanical automation in plastic weaving enterprises

Rising labor costs are driving more and more companies to transform from labor-intensive to highly automated operations. In the long run, high levels of automation in production should be a key advantage for plastic weaving companies in international trade competition.

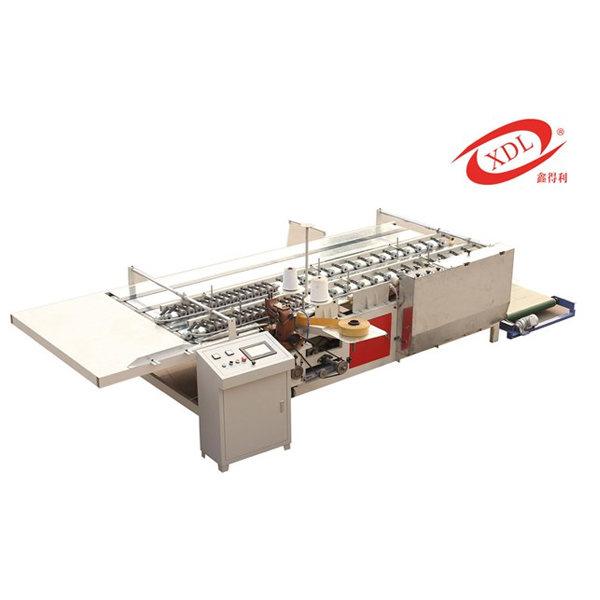

Take sewing, an essential process in woven bag companies, as an example. Generally, the monthly salary of post-processing workers in a northern plastic woven company should be around 2,000-3,000, so the annual salary should be around 22,000-33,000. A skilled sewing worker can sew 5,000 woven bags in one day, while an ordinary novice can only sew 3,000 woven bags a day. However, this kind of labor intensity is very high, and it is equivalent to only three and a half hours of work for an automatic woven bag sewing machine. An automatic sewing machine and a skilled operator can easily sew about 15,000 woven bags a day, which is equivalent to the workload of 3 skilled workers or 5 novices. Moreover, a worker who has never used an automatic single sewing machine can start working immediately after receiving simple training. This is undoubtedly good news for plastic weaving companies with a shortage of workers, and the company can save 20,000 to 30,000 yuan in costs.

The manufacturer of the smokeless knife cutting and sewing machine tells you: The other is an old-fashioned resistance wire cutting machine commonly used by small plastic knitting companies, which uses electric heating resistance wire to fuse the woven fabric to a certain temperature. This kind of resistance wire and sheet has high temperature and is easy to be stretched or broken. The temperature is low, the cutting speed is slow, and the labor intensity is high. Cutting bags per minute: 20-30 bags/minute. The new generation of automatic cutting machines uses cutters made of high-temperature heat-resistant steel and high-performance alloy tool steel. The cuts are neat and can automatically rub the mouth to facilitate subsequent operations. The PLC and servo motor are controlled together to achieve high cutting accuracy and good synchronization performance, thus greatly improving the efficiency. About 60-70 bags can be cut per minute, which greatly improves the work efficiency of the enterprise. This is equivalent to one person being able to do the work of the past two days in one day, and the operation is simple and easy to learn. It is very popular among small and medium-sized plastic knitting companies.

Say goodbye to the traditional ordinary iron rollers that require constant manual addition of thinner to adjust ink viscosity. The new anilox roller inking machine simplifies operation, providing efficient ink storage, even distribution, and precise ink transfer for clear printing. PLC control ensures stable operation and high printing speed, reaching approximately 2400 prints per hour. An ink receiving trough ensures cleanliness of the machine and the work area. The automatic counting function also facilitates bundling and packaging, improving work efficiency. Yangxin Xindeli Packaging Machinery provides customers with time-saving, labor-saving, and fully automatic cutting, sewing, printing, and collecting machines. Welcome to visit our factory for purchase.