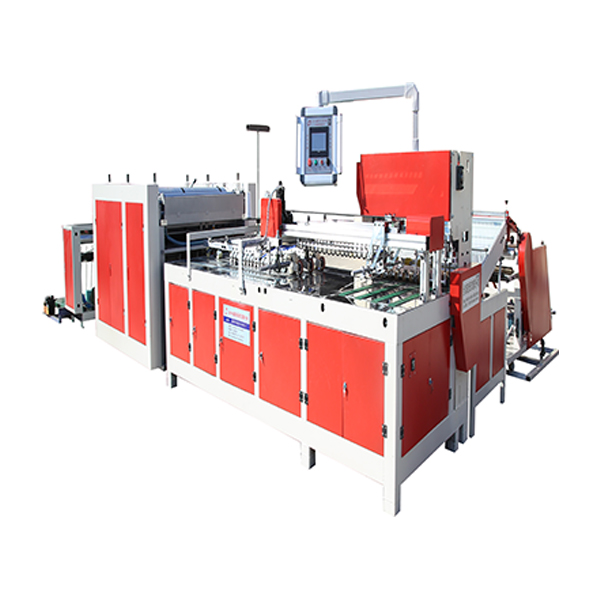

Smokeless knife cutting, sewing, printing and collecting machine

The smokeless cutting, sewing, printing, and collecting machine is a core piece of equipment in the entire woven bag production process. Specifically designed for PP, PE, and laminated woven bags, it innovatively integrates four functions: smokeless hot cutting, automated sewing, precise printing, and intelligent material collection. This enables integrated operation from fabric loading and automatic correction to finished product stacking. The equipment's core is the linkage between the smokeless cutting head and the servo printing system. During cutting, instantaneous high-temperature edge sealing prevents fraying; during printing, precise color registration prevents smudging; and a built-in negative pressure purification module simultaneously absorbs odors, ensuring a completely smokeless and environmentally friendly process.

I. Product Overview

The smokeless cutting, sewing, printing, and receiving integrated machine is the core equipment for the entire woven bag production process. Specifically designed for PP, PE, and laminated woven bags, it innovatively integrates four major functions: smokeless hot cutting, automated sewing, precise printing, and intelligent material receiving. This enables integrated operation from fabric feeding and automatic correction to finished product stacking. The equipment's core is the linkage between the smokeless cutting head and the servo printing system. During cutting, instantaneous high-temperature edge sealing prevents fraying; during printing, precise color registration prevents smudging; and a built-in negative pressure purification module simultaneously absorbs odors, ensuring a completely smokeless and environmentally friendly process. Equipped with a PLC intelligent control system, it can flexibly adapt to different specifications and printing needs, completely solving the pain points of traditional production processes—"dispersed processes and cumbersome turnover"—and significantly improving production continuity.

2. Core advantages

1. Integrated and efficient: The four processes are seamlessly connected, eliminating the need for semi-finished product turnover and secondary loading. The efficiency is significantly improved compared to traditional equipment. With the continuous feeding system, stable mass production can be achieved 24 hours a day, helping to double production capacity.

2. Environmentally friendly and high-quality: The cutting and purification systems operate simultaneously, producing no smoke or odor, meeting environmental standards; the printing module ensures clear and durable patterns, and the heat-cutting technology makes the bag opening flat and tear-resistant, achieving both environmental protection and quality standards.

3. Intelligent and labor-saving: Centralized control via high-definition touchscreen, supports multi-specification memory, automatic parameter adjustment during order change, quick start for beginners, one person can manage the entire production line, significantly reducing labor costs compared to the traditional model.

4. Stable and low power consumption: The industrial-grade servo system ensures precise cutting and printing positioning, uniform sewing stitches, and neat material collection and stacking, effectively reducing waste and rework, and significantly improving the finished product qualification rate.

3. Application fields

Leveraging its advantages across the entire process, the equipment is adaptable to the needs of multiple fields: in agriculture, it processes printed fertilizer and seed bags with clear markings for easy traceability; in industry, it produces printed cement and building material bags with wear-resistant properties suitable for heavy handling; in the food industry, it creates printed rice and flour bags with no loose fibers or odors, meeting safety standards; at the same time, it meets the mass production needs of printing on express delivery bags and promotional bags, balancing efficiency and brand display.